Robotics Machining Cell

Robocell Automation recognizes the challenges faced by manufacturers in finding qualified workers and the need to maintain seamless production lines. To address this issue, more and more companies are embracing industrial robots as a solution.

Robocell Automation is committed to providing tailored robotic solutions for machine tending applications. Our expertise in robotic integration enables us to seamlessly integrate robots into your existing production lines, optimizing efficiency and productivity. With automated machine tending, you can streamline operations, reduce human error, and meet production demands consistently.

Our team of experts works closely with you to understand your specific requirements, ensuring that the robotic solution we design aligns perfectly with your needs. We prioritize reliability, safety, and performance in every aspect of our robotic systems, ensuring a seamless and productive transition to automated machine tending.

Machining Robots: Robots for Loading and Unloading CNC Machines

The machining industry – including capital equipment like lathes, mills, machining centers, forges, presses, and injection molding machines – has been the backbone of manufacturing. It is highly likely that any job shops and manufacturing plants are looking to invest in some type of automation as skilled labor becomes harder to find and retain.

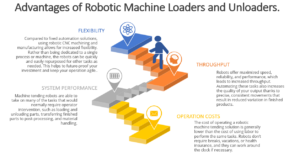

Automating these machines gives manufacturers clear advantages in terms of utilization, secondary processes, labor resources, and productivity. Anytime a machine sits idle or an operator isn’t available to support it that equates to lost productivity and profits.

Robocell Automation robotic machine tending solutions make it easy to connect your equipment and improve throughput and overall equipment effectiveness for most machine tending applications.

Solutions for Robotic Machining and Machine Tending Robots

Robocell Automation has decades of experience providing a wide range of robots for manufacturing CNC machines to automate a variety of processes, including:

Loading and unloading raw materials

Transferring finished parts to post-processing

Upstream and downstream assembly tasks

Material handling

From collaborative robots to robotic arms, our solutions are designed to help you get the most out of your machines by automating them with little to no down time.

A well-designed material handling system can:

- Eliminate redundant work, free up valuable labor, reduce costs

- Improve material delivery reliability, enhance customer care

- Decrease repetitive tasks and lifting injuries, increase safety

- Gain a stress-free process, improve working environment

- Maximize facility footprint, increase warehouse value

EMPLOYEE SAFETY AND SATISFACTION

By automating the strenuous and repetitive tasks of loading and unloading with CNC machining automation operations, you can reduce the risk of employee injury, making their jobs much safer. When your employees don’t have to manually handle these arduous duties and can instead focus on higher value tasks, they will be more satisfied with their workplace, thereby decreasing turnover and limiting your need to specifically hire manual laborers in those positions.

How Automated CNC Machining Tools for Unloading and Loading Can Facilitate an Agile Manufacturing Approach

The implementation of automated machine tending tools can help create an agile manufacturing environment because the machines can be quickly reprogrammed to handle different parts, and they do not require skilled labor to operate. As a result, machine tending industrial robots can help manufacturing facilities rapidly respond to changes in customer demand.

In order to fully reap the benefits of an agile manufacturing approach, it is important to implement other supporting technologies and processes. An agile manufacturing approach will often make use of lean principles, just-in-time production, and flexible manufacturing systems. When these technologies and processes are combined with CNC machining, they can help create a truly agile manufacturing environment.

WHAT IS AGILE MANUFACTURING?

An agile manufacturing environment is one that is able to rapidly respond to changes in customer demand. In order to be truly agile, a manufacturing facility must have the ability to quickly adapt its production process to meet changing customer needs. This might mean rapidly designing and prototyping new products, or rapidly reconfiguring existing production lines to produce different types of parts.

Intelligent Functions for Automated Loading and Unloading Solutions

Robots equipped with intelligent functions can further improve the efficiency of your machine tending applications and streamline your production process. These functions might include the ability to automatically:

- Recognize and pick up different types of parts

- Load and unload parts from different machines

- Connect and disconnect hoses, cables, and other peripherals

- Clean and lubricate machines

- Provide real-time status updates to operators

CUSTOM APPLICATION

Whether a stand-alone cell or comprehensive production line, Robocell Automation can design and build systems to fit virtually any application. We have extensive experience with all facets of material handling process including: robotic product selection, product transfer, packing, palletizing, and loading/unloading.

When designing and building a system, we understand that every client’s facility and production requirements are different, so we factor product, payload, end-of-arm tooling, speed, facility layout, and floor space into original designs. A Robocell Automation material handling solution not only addresses how the product is handled, but how it moves through a facility.